Lawn Mower Automatic Choke Problems? Reasons and Solutions

A lawn mower’s automatic choke controls the air and fuel ratio in the engine to guarantee simple starting and peak performance. However, if it has issues, your mower won’t run smoothly.

Dirty choke plates, blocked choke springs, carburetor issues, faulty choke mechanisms, and electrical issues are some of the most common lawn mower automatic choke problems.

5 Lawn Mower Automatic Choke Problems (Solutions Included)

A lawn mower’s automatic choke issues might arise for several reasons. The following are some typical causes and fixes for issues with lawn mower automatic chokes:

Dirty Choke Plate

Your lawn mower’s choke panel may accumulate varnish or be covered in grass clippings. This can prevent the automated choke from working properly.

The airflow upon startup is controlled by the choke plate. The choke plate may not allow enough air to pass through during startup if it is clogged. The engine will have a hard time starting in this situation.

Additionally, you can see that the engine starts at first but stalls soon after. When the engine does not obtain the proper air-to-fuel ratio for ongoing operation, this occurs.

Fix:

Take the following actions to solve the problem of a dirty choke plate:

- Make sure the lawn mower is switched off first.

- Now, unplug the spark plug wire to stop unintentional starts.

- To access the choke plate, you must first remove the air filter element and cover.

- See whether there is any obvious dirt on the choke plate. It could appear as a greasy or sticky residue on the plate or other components nearby.

- Using an appropriate carburetor cleaner, clean the choke plate and the region surrounding it.

- Use a tiny brush and a cleaner to clean the choke plate.

- Check to see if the plate can move easily.

- Reassemble the air filter and cap after cleaning.

- Start the lawn mower by reconnecting the spark plug wire.

Blocked Choke Spring

The choke spring on your lawn mower can lose tension or become stuck. When it breaks down, starting the engine may be challenging.

The choke spring may rust or corrode over time from exposure to moisture and environmental causes. This can prevent it from moving and getting stuck. Friction and stiffness can also result from a lack of lubrication.

Your mower’s choke spring may not open or close as rapidly as it should if it is broken. The engine needs a stronger fuel-to-air combination when it’s cold outside. This procedure can be hampered by a blocked choke spring.

Fix:

First, you should locate the choke spring. Either a separate housing or the carburetor itself may contain it. You should now look for corrosion or rust on the choke spring. Try lightly pushing it to see if it moves easily.

Apply the appropriate lubricant to the spring’s moving portions if it is not lubricated and the spring is stuck. It can move more easily as a result. You should avoid heavy lubrication because it could draw dirt and debris.

You might need to use fine-grit sandpaper to carefully remove the rust from the spring if it is corroded or rusted. Finally, apply a thin layer of lubricant once the rust has been removed to stop further corrosion.

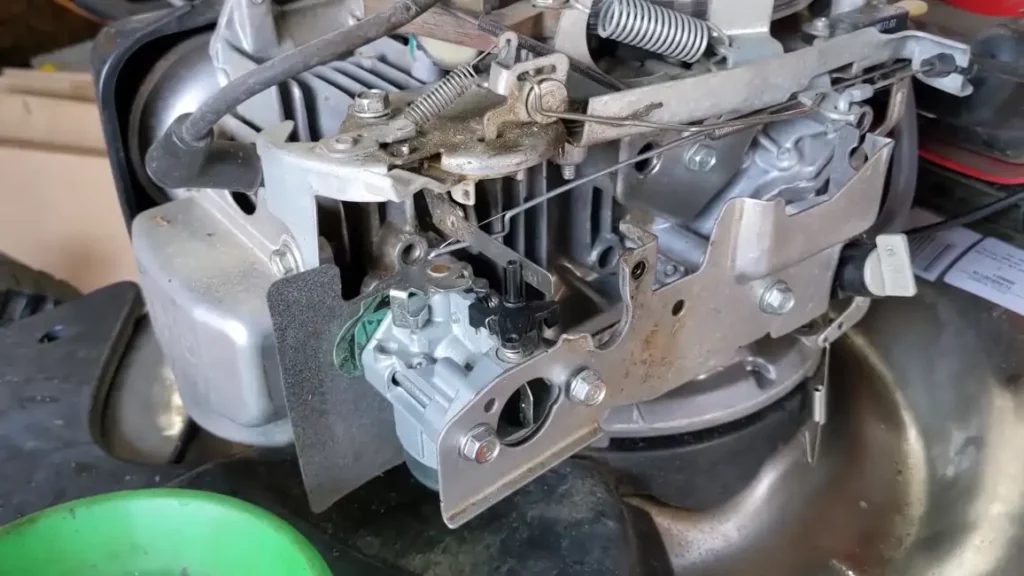

Carburetor Issues

The performance of the engine can be affected by carburetor issues. It may also affect how well the choke works. Old fuel residue can build up in the passageways. This affects the air and fuel flow.

A malfunctioning needle valve or a blocked float can both stop the flow of fuel. Your lawn mower’s automatic choke may not close or may stay closed even after the engine has warmed up if these issues arise.

Additionally, it might cause an engine to run overly rich or too lean. This will affect performance overall or idle. So, you can see that the engine is about to stall.

Fix:

Here is a step-by-step tutorial for resolving the problems:

- Remove the air filter cover to gain access to the carburetor first.

- Analyze the carburetor’s parts. Check the ports and jets for obstructions.

- To carefully remove any clogs, use compressed air and a carburetor cleaner.

- Verify the appropriate working of the float and needle valve mechanism.

- Check to see if the needle valve is sticking and that the float slides smoothly.

- Replace any worn-out or broken parts.

- Take the lawnmower to a qualified mechanic if you think carburetor modifications are required.

Faulty Choke Mechanism

A faulty choke mechanism is one of the most reported lawn mower automatic choke problems. The engine won’t start as a result. The physical toll can wear down or break certain sections of the choke mechanism over time.

Additionally, vibration can cause the choke mechanism’s levers and links to fall out of alignment. The choke mechanism can experience wear with regular use. These all result in decreased functionality.

You may notice that the choke is functioning randomly. Because of this, starting the mower’s engine will be difficult.

Fix:

Check each part of the choke mechanism. Look for any obvious damage on the levers, couplings, and springs.

You should make sure that every part is linked and aligned correctly. As necessary, adjust or rearrange the components.

Replace any worn or damaged parts with appropriate replacements if you find them. To ensure the smooth operation of the choke mechanism, lubricate the moving components.

Electrical Issue

The automatic choke system’s wiring or electrical components may suffer damage.

The choke won’t engage or disengage as it should if this occurs. As a result, your mower won’t start since the choke isn’t getting enough power.

Fix:

To resolve this problem, disconnect the spark plug wire. Now, examine the connections and wiring for the choke system.

If you see any broken wires or connectors, change them. Also, make sure the electrical parts are working properly, particularly the choke solenoid. Now, you should reattach the spark plug wire, and then check the choke’s functionality.

How To Interpret Engine Choke Symbols On Lawn Mowers?

To troubleshoot the lawn mower automatic choke problems, you must know about the different choke symbols. They offer guidance on when and how to use the choke for effective engine starting and operation.

The meanings of some typical choke symbols are listed below:

- Open Choke Symbol: An open rectangle is a common symbol for the open choke. This sign denotes that the choke is open or switched off. The carburetor of your mower will receive the most airflow while the choke is open.

- Closed Choke Symbol: The closed choke symbol is noted with a filled rectangle. It denotes that the choke is closed or turned on. By limiting airflow into the carburetor, closing the choke results in a richer fuel-to-air combination.

- Half-Choke Symbol: The half-choke symbol is a rectangle that is only partially filled. When the engine is just partially warmed up and a somewhat richer mixture is needed, the engine must be in this condition.

Frequently Asked Questions (FAQs):

Can I turn off my lawn mower’s automatic choke?

Although it is possible, you should not disable the automatic choke. Disabling it might cause performance problems.

Can I change my lawn mower’s automatic choke settings?

Yes, the automatic choke settings may frequently be changed.

How frequently should I clean my lawn mower’s automatic choke?

You should clean your lawn mower’s automatic choke 1-2 times every year.

How can I tell if the automatic choke on my mower is operating properly?

When the engine runs well and the automatic choke adjusts smoothly during cold starts and warm-ups, it is functioning properly.