Zero Turn Mower Blades Won’t Engage: Reasons & Fixes Explained

Nothing is more annoying than a zero-turn mower that won’t engage the blades, leaving your grass uncut and wasting your time. You are not the only one who is dealing with this issue.

If the PTO switch is broken, the belt is damaged or worn, or there are faulty pulleys and bad clutch the zero turn mower blades won’t engage. This article will look into potential causes, and assist you in troubleshooting it.

7 Reasons Behind Zero Turn Mower Blades Won’t Engage

1. Faulty PTO switch

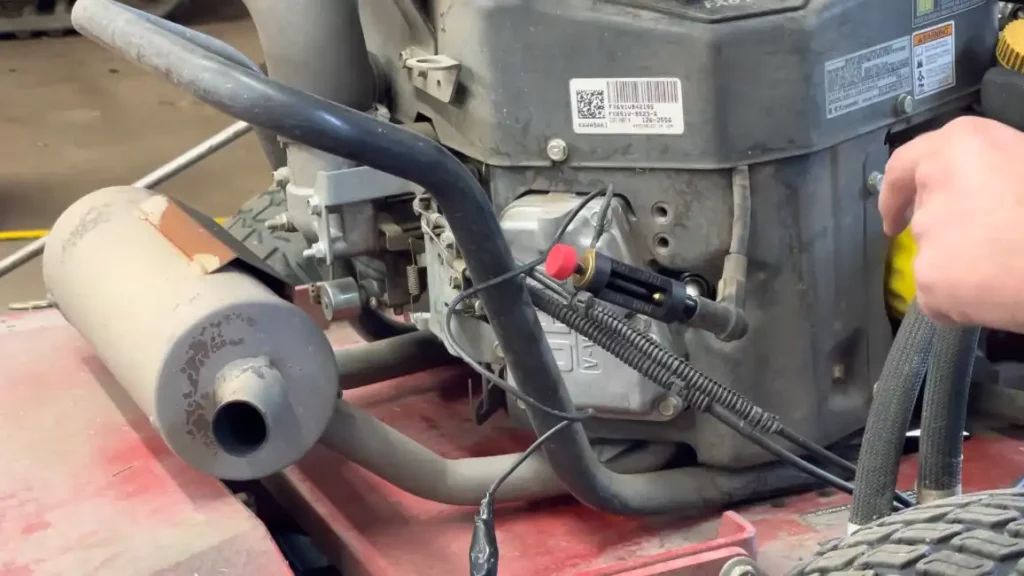

If the blades on your zero turn mower won’t engage, a possible culprit is a faulty blade engagement switch, also known as the power take-off (PTO) switch.

The PTO switch is responsible for activating the blades when you want to start mowing. If this switch is not functioning properly, it can prevent the blades from engaging.

The Fix

To troubleshoot a faulty PTO switch, you can try the following steps:

- Check the switch: Inspect the PTO switch for any visible damage or signs of wear. Make sure it is in the correct position and not stuck in between.

- Test the switch: Use a multimeter to test the continuity of the PTO switch. This will help determine if the switch is functioning properly or if it needs to be replaced.

- Replace the switch: If the switch is found to be faulty, it will need to be replaced. Consult the user manual or contact the manufacturer for the correct replacement part and instructions on how to install it.

2. Broken or Worn-out Belt

A worn deck belt can indeed result in insufficient grip on the pulleys, causing it to slip. This can lead to the blades not engaging properly.

Signs of a worn deck belt include cracks, stretching, fraying, or a glazed appearance. Additionally, a thinner belt that sits deep in the pulley grooves is also an indication of a worn belt

The Fix

To fix this problem:

- If you observe signs of wear on the belt, it is recommended to replace it.

- Even if the belt isn’t the primary cause of the blade engagement issue, it’s crucial to replace it once wear is evident.

- The belt’s grip on the pulleys directly impacts blade speed, essential for generating the necessary suction to lift grass and ensure an even cut.

3. Damaged or Misaligned Mower Deck

A damaged or misaligned mower deck can cause blade misalignment, preventing proper engagement.

This can lead to difficulties in starting and running the mower, stalling during blade engagement, or the zero turn mower blades won’t engage at all.

The Fix:

- Visually inspect the mower deck for signs of bending, damage, or misalignment.

- Look for visible dents, cracks, or indications of damage.

- If issues are observed, consider repairing or replacing the deck according to the manufacturer’s guidelines.

4. Worn Idler Tensioner

In a zero-turn mower, the tensioner bracket and spring maintain the alignment of idler pulleys, crucial for proper belt tension.

Over time, the bracket hole for spring attachment can wear, or the spring itself may become worn or break, leading to loose belts and disengaged blades.

The Fix

To replace a worn idler tensioner:

- Inspect bracket and spring for wear or damage.

- Order compatible replacement parts from manufacturer or authorized dealers.

- Remove old bracket and spring, loosening securing bolts or screws.

- Install new bracket, securing it in place with appropriate hardware.

- Attach new spring, ensuring proper alignment and tension.

- Adjust tension per manufacturer’s instructions to achieve proper belt tension for engaged blades.

5. Bad Pulley Bearing

If the belt on your zero-turn mower keeps coming off, one possible cause could be bad bearings in the pulleys

When the bearings in a pulley fail, it can cause the pulley to move, resulting in it no longer sitting flat and parallel to the deck. This misalignment can cause the belt to roll off the pulley, preventing the blades from engaging properly.

The Fix

Here are the steps to address this issue:

- Inspect pulleys for wear, damage, or bearing failure.

- Identify pulleys not sitting flat or parallel to the deck as potential problem areas.

- Replace the affected pulley with a new one.

- Contact the manufacturer or authorized dealers for a correct replacement part.

- Follow manufacturer’s instructions to install the new pulley.

- Ensure proper alignment and secure attachment to the deck.

6. Bad Clutch

Blades not engaging on a zero turn mower may be due to a worn or faulty PTO clutch. PTO clutch transfers power from engine to blades via the drive belt.

Worn or faulty clutch can fail to engage the drive belt, resulting in non-turning blades.

The Fix

- Inspect PTO clutch for wear, damage, or malfunction.

- Look for visible signs of wear or loose connections.

- Obtain correct replacement PTO clutch from manufacturer or authorized dealers.

- Ensure compatibility with specific mower model.

- Follow manufacturer’s instructions for removal and installation.

- Properly align and secure the new clutch according to provided guidelines.

7. Week Battery

A weak battery can indeed affect the operation of an electric clutch, which is responsible for engaging the mower blades on a zero-turn mower. If the battery is not able to provide sufficient power to the clutch solenoid, the blades may fail to engage.

The Fix

To check for a weak battery on your mower:

- Locate the battery, often found under the hood or seat, and uncover it if needed with a screwdriver.

- Set a multimeter to DC voltage and connect the red probe to the positive terminal and the black probe to the negative terminal. A fully charged 12-volt battery should read around 12.7 volts. A significantly lower reading indicates a weak battery.

- If voltage is low, charge the battery following safety guidelines and manufacturer instructions.

- Connect the positive charger cable to the positive battery terminal.

- Attach the negative charger cable to the negative battery terminal.

- Set voltage and amperage (start with low, around 2 amps).

- Charge until desired voltage is reached.

- If the battery can’t hold a charge or is old, consider replacement. Look for a new battery with at least 300 CCA. Check if a core exchange is required when purchasing a new battery.

Related Post: How to Solve Lawn Mower Vibrates After Changing Blade: A Guide for a Smooth Cut

Frequently Asked Question [FAQs]

Why won’t my zero turn mower blades engage?

There could be several reasons for this issue, including a faulty switch, belt problems, or mechanical issues.

How do zero turn mowers work?

Zero turn mowers are designed to maneuver easily and efficiently. They have two independently controlled rear wheels that allow for quick turning without the need for a wide turning radius.

How can I maintain my zero turn mower to prevent blade engagement issues?

Regular maintenance is crucial for keeping your zero turn mower in optimal condition. This includes cleaning the mower deck, sharpening blades, lubricating moving parts, and inspecting belts and pulleys for wear.